If you look around in the production hall of the space travel company Isar Aerospace in the southeast of Munich, you are looking for parts of the 28-meter rocket that builds the start-up here in Ottobrunn: At one point there are structures for the lower level, a tank and in another area the future rocket tip. The most important part of a rocket stands almost a little unnoticed on a small trolley, right with the 3D printers for the combustion chamber: the self-developed Aquila engine without the rocket called Spectrum could never take off. About half a meter high and weighing 20 kilos, it can unleash a thrust of about 75 kilonewton. This means that the engine can raise seven and a half tons of weight. 75 kilonewton – that corresponds approximately to the power of one Eurofighter-Hourg, says company boss and founder Daniel Metzler, 32.

Soon nine such engines will raise the rocket. There, a tenth engine is supposed to drive the upper level that exposes the payload, i.e. the satellites in the earth orbit. Fueled by liquid oxygen and propane, a comparatively clean drive, according to the start-up, which does not burden the environment less.

The first rocket is already on the starting ramp in Norway, a team from Isar Aerospace is preparing the Spectrum For the first flight for a few weeks. The last tests with the rocket levels and engines were successful in February. And after the Norwegian civil aviation authority (NCAA) approved the start last Friday, the founders want to shoot the Microlaunter into space on Monday depending on the weather, the potential time window for the “Going Full Spectrum” mission until Sunday next week.

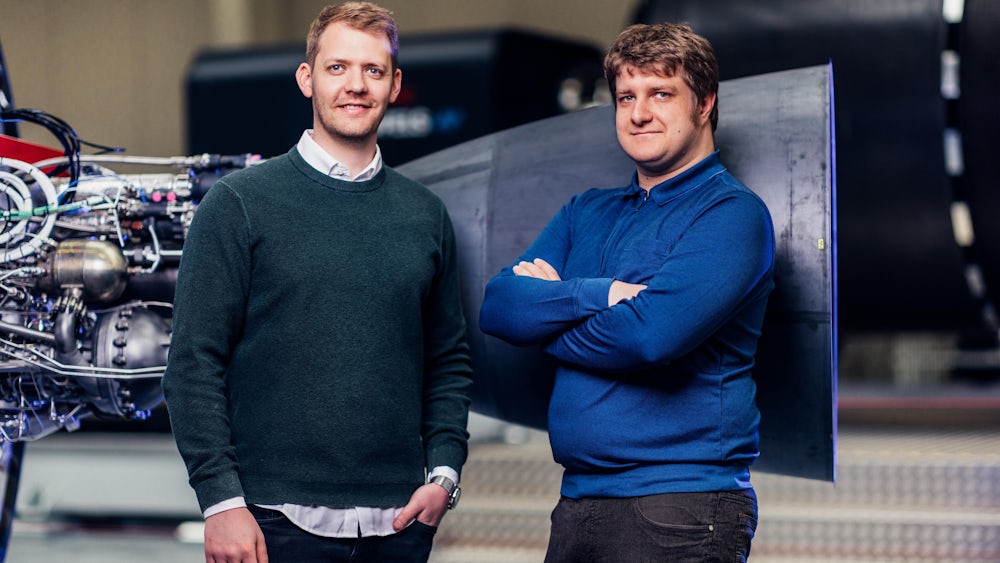

Metzler tries to screw down expectations. “You have to prepare for the fact that we will probably not reach the orbit at the beginning, and that's totally okay,” he says. Ultimately, it is the first test flight without customer protection loads and “the first integrated test of tens of thousands of components,” says co-founder and chief of technology Josef Fleischmann, 34. So there are many thousand potential sources of error. It's just rocket science.

After all, the engineers can simulate a lot on the computer, test parts of the rocket in the thermal vacuum chamber or shake through the so -called shaker. However, this cannot replace a flight and the fight against gravity. “Regardless of how far we get, we will hopefully gain an enormous amount of data and experience,” says Fleischmann. “From this we can learn for the next flights.” One could say that madmen belongs to the business model. This philosophy seems familiar to you, the Californian space company Space-X has it with its Falcon-Rakets presented.

Welcome to a flagship company of the so-called New Space area, in which young, hip companies try unconventional and shirt-sleeved to make space cheaper-also in favor of taxpayers. This means shorter decision -making channels, unusual procedures or a lower dependence on suppliers, which can result in faster development and production. Or just a failure.

The founders, Metzler, Fleischmann and Markus Brandl, know each other from the TU Munich. There they studied together, aerospace or mechanical engineering, and already developed small rockets together.

When the start-up, founded in 2018, opened its factory in Ottobrunn two years later, about a hundred people belonged to the team, now there are four times as many, they come from 50 countries. The founders rely on the concept of “experiment and error” from the start. Even with the machines you bought. They used the long delivery times for these machines to Spectrum to develop. They built a rocket, so to speak, that was adapted to future machines and not the other way around. The division.

On the other hand, in Ottobrunn you always try to optimize the overall system. In other words, if individually improved components have a negative impact on the rocket in interaction, these parts have to get a little worse again. In order to be less dependent on suppliers, the young company builds almost 90 percent of the parts themselves. So you can quickly try out variants and save a lot of time back and forth with manufacturers. “We have the complete production chain with us in -house from the raw material to the integrated rocket engine,” says Metzler. Exceptions are, for example, electronic elements such as microchips that would be bought. Most tests also happen in the house, as the founders not only test randomly. In this way, several rockets could be produced in parallel. While the rocket for the first flight has long been in Norway, the next two rockets are being built in Ottobrunn.

The Porsche Holding is among the donors.

The engine was one of the first challenges after the company was founded seven years ago. It is crucial to optimize the rocket. The development lasts two or three years, says Metzler. The 3D printer production is successful within a week. Metzler wants to manufacture several hundred engines every year, he also needs them in the medium term.

At the current location, which is 8,000 square meters in size, the company can produce about ten rockets annually. Isar Aerospace is building about 20 kilometers from Ottobrunn a new factory, which can be created five times as large, in which 40 rockets can be created a year.

The company's strategy arrives at the investors. The founders are among the best-financed start-ups in the industry across Europe. They collected 400 million euros, in 2024 a NATO fund got on. The donors also include Airbus Ventures, Earlybird, Lakestar, Vsquared and the Porsche Holding. But also private individuals such as Bulent Altan or the economist Ann-Kristin Achleitner and her husband Paul Achleitner.

Bulent Altan was an engineer at Elon Musk's rocket company Space-X and is now investing in European space travel. “I had already looked at a lot of launch-ups and was mostly quite skeptical,” he told the SZ. However, it was always about finding a competitive niche against Space-X, but that was not possible. Altan does not see that he brought the culture from Space-X to Isar Aerospace. “My job was more to be at your side with experience and expertise and, of course, to tell a spacecraft. Metzler himself built up a company that has such a culture. Altan sees itself as a sparring partner: “I often meet engineers in my free time to exchange ideas,” he says.

In fact, the founders have taken over the concept of Space-X to do as much as possible. This is the only way to optimally coordinate the components, says Metzler. Isar Aerospace has a lot automated, but many people also work here in Ottobrunn. In the welding area there are loudspeaker boxes from which staccato -like rhythms come. The music mixes with the sustainable sound of the welding equipment. Right in the middle of Emmanuel, it is his first job in the space industry, says the Frenchman. His colleague built the boxes, “we cannot work without music”.

There are several 3D printers on the other side of the hall. They are named after astronauts: Apollo-11 moon drivers, Gemini astronauts. While the rockets were made of steel in the 1960s and 1970s, Isar Aerospace decided on the more expensive carbon fiber during cladding and tanks. Not because it is easier than steel that the production of carbon missiles can be better automated.

In design, Isar Aerospace also took into account that at least the lower level was able to use several times. For the upper level, this is only useful for economic reasons for very large racers. It is quite possible that his start-up is moving into this division. “We certainly have larger ambitions,” said Metzler in 2023 at the SZ economic summit. Isar Aerospace can make rocket starts more cheaper by a factor of ten. ESA boss Josef Aschbacher wants to support the manufacturers of microlaunchers. “Our goal is to develop at least two microla launchers into a heavy launcher in the 1930s,” he says. The ESA had provided 25 million euros for a microla launch competition from the German space agency. Soon she wants to advertise a competition for new carriers, “this is an important program for us,” said Metzler.

Now it's about the microlaunchers, of which Isar Aerospace initially wants to build ten a year. The two -stage Spectrum should transport a ton of payload into the lower earth orbit. For comparison: the new one Ariane 6 has a capacity of around ten tons for this orbit.

Metzler sees a growing market for smaller rockets, has bookings until 2027 and calls customers like Airbus and ESA. Most recently, the Norwegian space agency Isar Aerospace has commissioned to start two satellites to monitor the Arctic Ocean.

With a small rocket, customers can bring their satellites more flexible and more targeted. Small and medium -sized satellites can only start on large rockets on so -called rideshare flights with many other payloads. This can mean long waiting times, and the orgores may not be flown in.

But are there enough commercial and institutional customers for rocket builders like Isar Aerospace to survive? The Abrupt departure from the United States from Europe and the escapades of Space-X boss Elon Musk could benefit the local rocket manufacturers. European customers with smaller satellites may be popular with Musk's popular rocket Falcon 9 waive. Especially since Europe is now pursuing the goal of becoming more independent of the United States in space travel – acting confidently.

Apart from that, investors expect rising billions in space in space travel. For 2027, for example, the PWC 70 starts with microl launchers awaits-twice as many as 2023. However, there are around 15 launch-ups in Europe alone. “The success of the first flight is crucial because a failure leads to financial pressure, as Virgin Orbit's bankruptcy shows after a failed attempt to start,” writes PWC. Founded by billionaire Richard Branson, Virgin Orbit 2023 went into bankruptcy proceedings.

Isar Aerospace would be the first German rocket builder to make it into space. HyImp pulses has a year ago with its smaller altitude research rocket SR75 reached about 50 to 60 kilometers, the actual microlauncher should still come. RFA is aiming for the second half of the year for its premiere. “We are approaching the most important moment of our previous trip,” says Daniel Metzler. But for him the start is just another piece of the puzzle. “Europe lacks autonomous, regular access to space and corresponding skills,” says Metzler. To do this must Spectrum But first overcome gravity. “Rakets are and remain technical masterpieces, you move permanently on the edge of the physically just possible.”

In an earlier version there was talk that Isar Aerospace had bookings by 2032 and customers such as Amazon and John Deere. This is not correct, we corrected it. We also updated the start date.